Directional Drilling

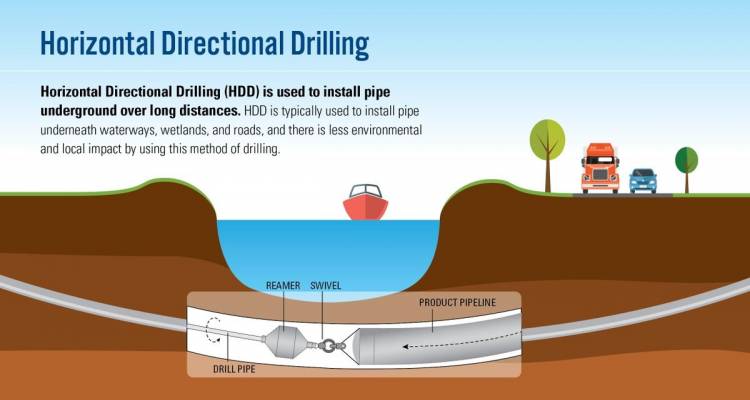

Horizontal directional drilling (HDD) is a basic trenchless technology that involves drilling into the earth to create a horizontal bore under the surface along a planned pathway through which pipes and conduits may pass.

HDD method is about making a horizontal borehole from one location to another. The process typically begins with boring a small pilot hole along the desired centerline of a proposed profile under the crossing obstacle (e.g., a highway) with a continuous string of steel drill rod. The position of the drill head can be accurately controlled with devices and sensors that monitor and track the drill head. Through small adjustments made by the operator, the drill head can go around trees, under foundations, buried utilities, lakes, or other obstructions.

When the bore head and rod emerge on the opposite side of the crossing, usually a special cutter, called a back reamer, is attached and pulled back through the pilot hole. The reamer bores out the pilot hole so that the pipe can be pulled through. The pipe is usually pulled through from the side of the crossing opposite the drill rig.

HDD has become the preferred method for underground installation of:

- Water & Sewer Lines

- Gas & Oil Lines

- Geothermal

- Fiber Optic, Communication & Power Cables

Directional Drilling is preferred for many reasons including lower cost, less mess, less noise, quicker completion, minimal surface disruption, less environmental Impact, and deeper installations, just to name a few.

Contact us today to discuss your project and see if directional drilling is the best option for you.